For OEM buyers sourcing pickleball paddles, the Pickleball Paddle Edge Guard may seem like a simple structural feature. However, the edge guard plays a critical role in protecting the paddle’s core integrity and overall durability. In reality, 95% of factories struggle to fully control edge guard reinforcement quality, especially under large production volumes.

The Pickleball Paddle Edge Guard is one of the most overlooked components that directly influences long-term paddle integrity. Identifying quality control (QC) blind spots in edge guard assembly can help buyers avoid costly returns, warranty claims, and customer dissatisfaction. Here are the five most common issues found during manufacturing. A poorly assembled Pickleball Paddle Edge Guard can lead to long-term durability issues, directly increasing return rates for OEM buyers.

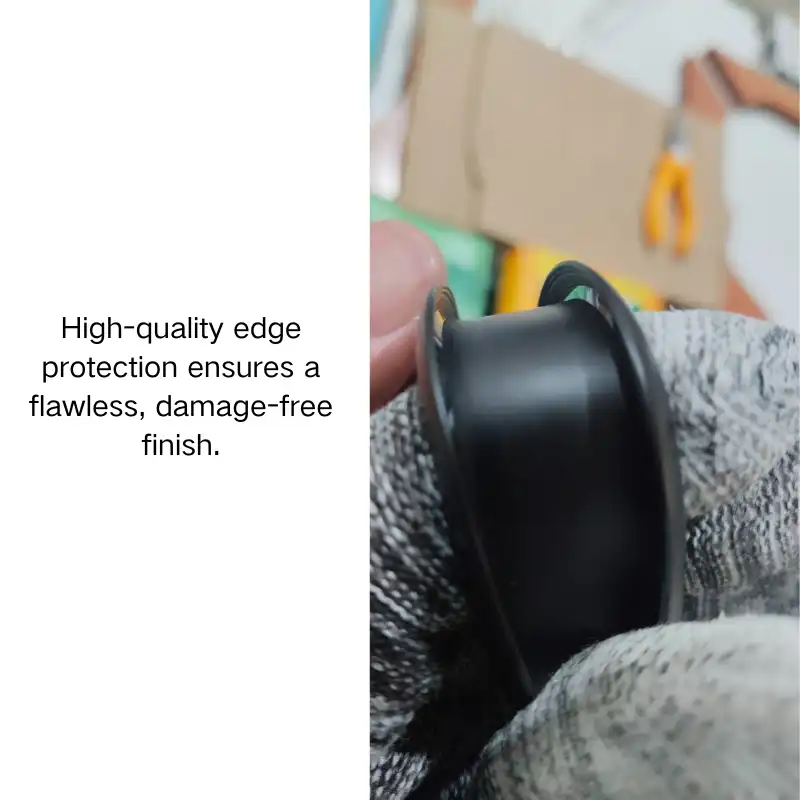

1. Pickleball Paddle Edge Guard Adhesive Problems

One of the most frequent quality control (QC) failures occurs during glue application. The edge guard is bonded to the paddle’s rim using specialized adhesives. Thicker pickleball paddles, typically ranging from 13mm to 16mm, present added challenges because the larger bonding surface requires more precise adhesive distribution. If the glue is applied unevenly — too much in some areas, too little in others — it can result in weak bonding points that compromise edge durability.

Inconsistent adhesive layers may cause the edge guard to peel off under impact or environmental stress. Even slight gaps can allow moisture intrusion, which over time compromises the core structure.

Pickleball Paddle Edge Guard Adhesive Problems

2. Overheating During Edge Sealing

Some factories use heat-assisted processes to help shape and secure the edge guard. However, poor temperature control is a common blind spot. Overheating can cause the plastic edge guard to soften or deform, resulting in warping, shrinking, or uneven alignment.

Proper temperature management is crucial to ensure stable bonding without compromising the plastic material’s shape and resilience.

Overheating During Edge Sealing

3. Uneven Pressure During Bonding

During edge guard installation, uniform pressure is applied along the entire paddle circumference to ensure tight adhesion. Insufficient or uneven pressure can lead to micro-gaps between the edge guard and paddle body.

These weak points may not be immediately visible but often become evident during actual gameplay, especially under lateral impacts or repeated ball strikes near the edge.

Uneven Pressure During Bonding

4. Alignment Errors During Assembly

Precise alignment during edge guard assembly is often overlooked. Even a slight misalignment can result in visible gaps, exposed paddle layers, or uneven edge thickness.

Visually, these defects affect product aesthetics. Functionally, they weaken edge protection and increase the risk of premature edge separation under heavy play.

Alignment Errors During Assembly

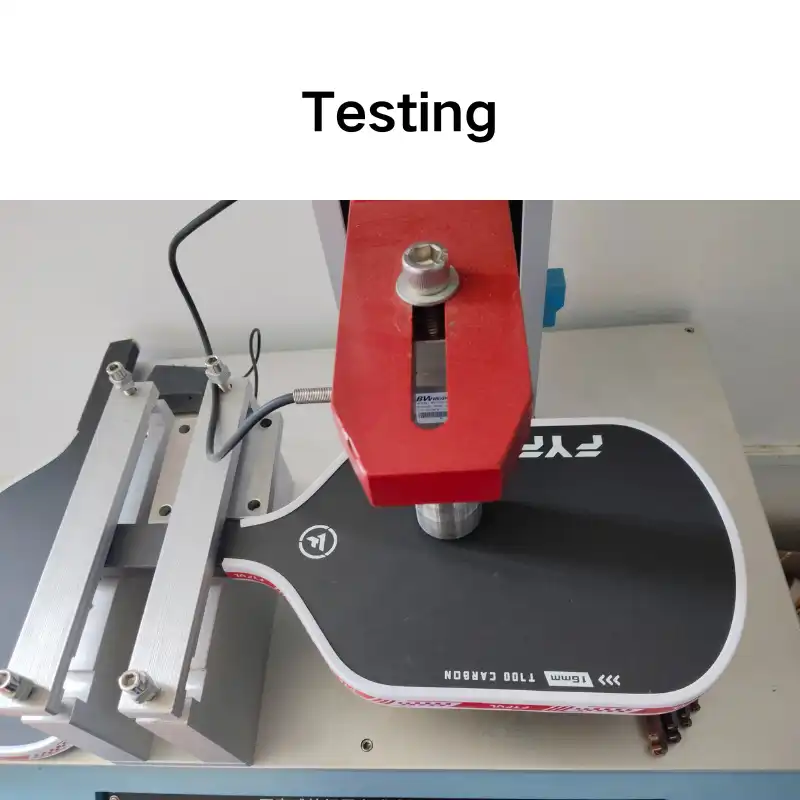

5. Missing Post-Assembly Stress Testing

Many factories skip or minimize post-assembly durability testing after edge guard installation. Without controlled flex tests, impact tests, or environmental simulations, latent weaknesses may go undetected before shipping.

Comprehensive QC protocols should include random batch testing that simulates real-world paddle stress, ensuring edge guards remain stable across production lots. Without proper testing, even small Pickleball Paddle Edge Guard defects can quickly escalate into major product failures in real-world use.

Stress Testing

Summary for Buyers

Though often overlooked, Pickleball Paddle Edge Guard quality has a direct impact on product durability and customer satisfaction. OEM buyers should pay close attention to adhesive application, temperature control, bonding pressure, alignment, and post-assembly testing during supplier audits. Controlling these critical steps reduces return rates and helps protect your brand’s long-term reputation.